Celebrating one year of SALIENT: An inventory of the project progress

The SALIENT project turned one year old in August 2023. The consortium partners met for a Consortium Meeting to celebrate the occasion, take inventory of the activities and findings at this moment in the project lifetime and plan the workplan for the upcoming two years. The meeting took place in person at the offices of consortium partner CRF (Fiat Research Centre) in Turin, Italy on 19 & 20 September 2023.

Many important milestones were reached especially in the last months leading up to the meeting, including the manufacturing and testing of new composite materials and the design of a new FES model, as well as the preparation of simulation environments to validate it.

The meeting was split into different thematic areas and work packages, which complemented and supported each other:

Material development: An important part of the new FES proposed by SALIENT is a new composite material, that will be more sustainable, lightweight and circular.

ASAS (Turkey) modified the chemical composition of 6xxx series aluminium alloy and produced a total of 24 tons on it, which was partly shipped to other consortium partners for further testing and creation of hybrid samples. (Picture 1 & 2)

CIDAUT (Spain) characterised the behaviour of the developed materials (AI alloy, composite TP/CFRP and composite reinforced with shape memory alloy wires) focusing on their performance and failure mechanisms in several load scenarios, which revealed very consistent and reliable results. They documented that the material fibre orientation and the geometry during the tests has a big impact on the performance of the composite material (see matrix below). (Pictures 3-5)

Fraunhofer IWU & ThermoPre (Germany) worked on developing hybrid materials by joining carbon fiber-reinforced thermoplastic tapes (CFPA6) with sandblasted aluminum in a press process. To enhance the adhesive strength, a special powder-based primer was used (see pictures 1 & 2 below) and on the other by merging the aluminum with a carbon layer (see pictures 3 & 4 below), which they merged using adhesive, powder and heat. (Pictures 6-8)

FES design: A 3D design of the new Front-End Structure was created to increase the safety and ability to absorb crash impacts.

CTAG (Spain) created a prefinal FES design and submitted it to VIF to validate it using simulations before they will go through the work of manufacturing the actual part, some changes may still be made to the design before it can be released and circulated to the industry. (Picture 9)

Fraunhofer institute (Germany) has also developed an innovative CFRP (Carbon Fiber Reinforced Plastic) crash box featuring a unique lay-up and crash mechanism for the new FES. This design enables significantly greater specific energy absorption compared to metal crash boxes, resulting in a low mass while providing high energy absorption capabilities. Furthermore, it promises exceptional durability, making it well-suited for circular economy approaches, as it can remain intact for extended periods.

Simulations: An important part of validating the designs and materials in theory and as a form of feasibility study, the FES design of different components and materials are subjected to simulated crashes and accidents to get a better understanding of how the parts may behave during a crash.

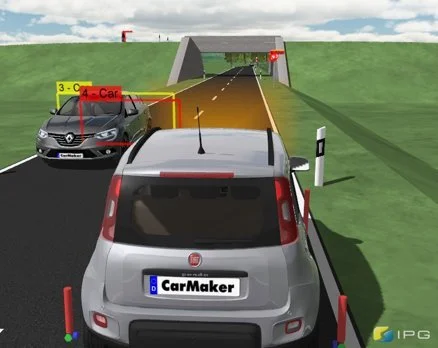

IPG Automotive (United Kingdom) have completed the simulation of the ADAS sensor system and also the vehicle itself. They are now dedicating time to defining and implementing the scenarios. (Pictures 10 & 11)

VIF (Austria) simulated the crash behaviour of the new FES design, using as an input the CAD file created by CTAG.

Overall, the meeting proved to be very fruitful and consisted in large parts of open debates and conversations between the different partners and their fields of activity to ensure a smooth cooperation across partners (coordination across languages, countries and even continents), work packages, thematic focuses, and deadlines within the wider project. The meeting was rounded off by a joint consortium dinner at a traditional Piedmontese restaurant in the centre of Turin, organised by the host of the meeting, the Fiat Research Centre (CRF).

The next year of the project will dive deeper into the evaluation and validation of the FES design and materials developed and the final year will bring all of the research together when the actual car component will be produced and crash tested. The next meeting of the consortium will be the Official Review Meeting with the European Commission in Brussels in February 2024, making the half-way mark of the project (18 months).

Authors: Friederike L. Kühl (Etelätär Innovation)